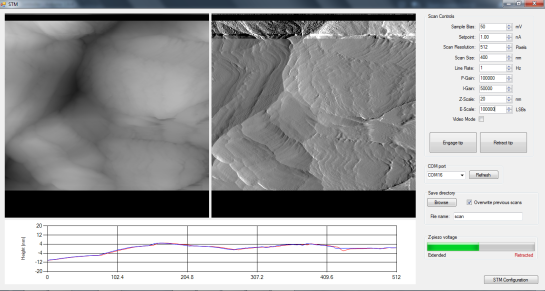

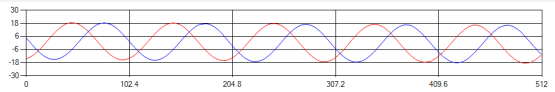

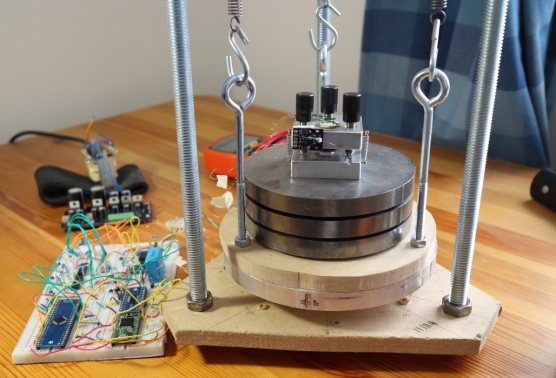

I recently motorized the coarse approach mechanism on my STM. The coarse approach is done by first fully extending the Z-piezo (reasonably slowly) to search for the surface. If it doesn’t find the surface, it fully retracts, and a stepper motor, which drives the rear fine-pitch screw on the STM, takes a few steps to move the tip close to the sample. The distance it moves is somewhat less than the Z-piezo travel. After moving the motor, the Z-piezo fully extends again to search for the sample surface. This process repeats until the piezo finds the surface. When this happens, the Z-piezo retracts one more time, and the motor adjusts the piezo height above the sample so that, when the scanner extends one last time, it will find the sample at about the center of its travel range (just to give it some room to drift in either direction). Once the sample surface is found the Z-feedback loop switches on, and scanning begins.

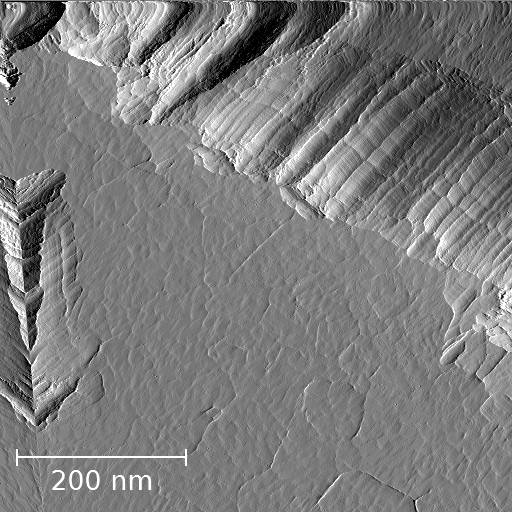

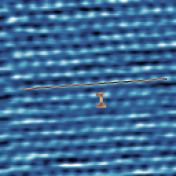

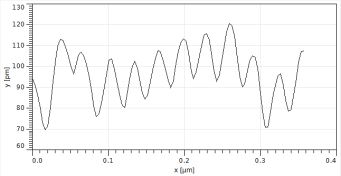

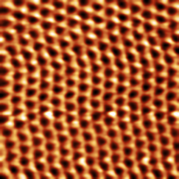

Here are some images zooming in on a gold surface taken after doing a motorized coarse approach. Note the lack of craters! I’ve applied some lighting effects in Gwyddion to help make the edges of the atomic terraces more apparent. No luck resolving individual atoms on metals yet though… I believe the issue is acoustic noise. Time to build a sound-proof box…

This technique is called the “woodpecker” approach, and it prevents vibrations from the motor from crashing the tip, since only the Z-piezo brings the tip and sample into contact. Since the hard part is done by the piezo, the motor step size only needs to be smaller than the piezo range, although it’s nice to have a smaller step size to be able to center the scanner in its travel range before beginning the scan.

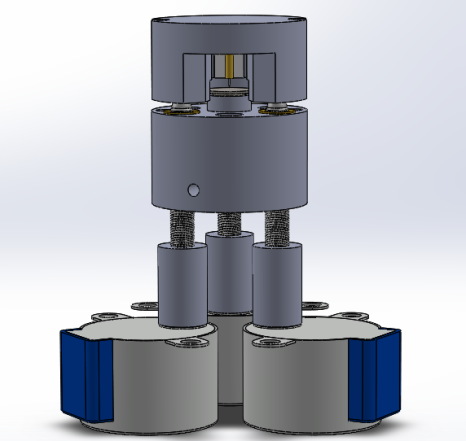

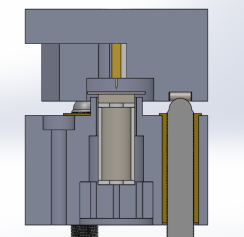

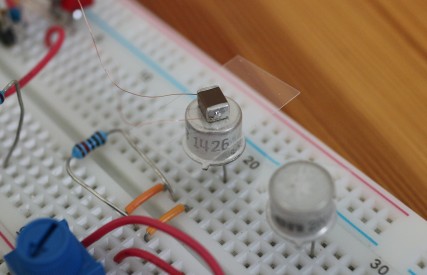

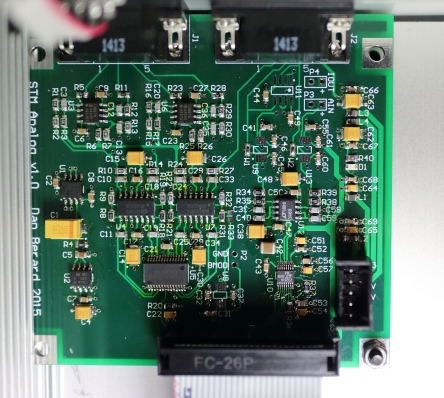

My scanner has about 700 nm vertical travel. Creating steps much smaller than this with a stepper motor is really no problem at all, especially since we don’t care about backlash. I used the 28byj-48 stepper motor to drive the rear fine-pitch screw on the STM. I milled a slot in the end of the screw’s plastic knob that fits over the motor shaft, while allowing the screw to move up and down. The 28byj-48 motor is very cheap and is geared down to about 2048 full steps/revolution. The fine screw moves 250 um/revolution, and the STM body’s lever reduction reduces the motion by a factor of about 20. This gives a step size of 250um/2048/20 = 6 nm.

There are a few subtleties that came up here: when the Z-feedback is switched on, the integral term first must be initialized to the current Z-value. Otherwise, the feedback will cause a small jump in the Z-piezo when it’s switched on, which crashes the tip! Took me a while to figure out why I was still seeing craters in my scans! Another issue is thermal drift. The motor produces a substantial amount of heat, which can cause the scanner to drift out of range within minutes. The solution is simply to turn the motor off when it’s not moving, i.e. when the piezo is extending and when the scan starts. This means that we can’t use microstepping, which is I used a geared motor in the first place. I’m also running the motor on 3.3V rather than 5V to further reduce heating.